Our Services

We currently offer following services to our clients

Design Services

Our detailed engineering departments Provides Detailed Solar Electrical & Structural Designs for Construction

In-Field Testing

Maximize your ROI using testing services to identify defects on your PV sites during construction or Operation.

O&M Tools & Equipment

Our Team uses Handheld thermal Cameras to inspect Solar arrays to detect anomalies and identify issues

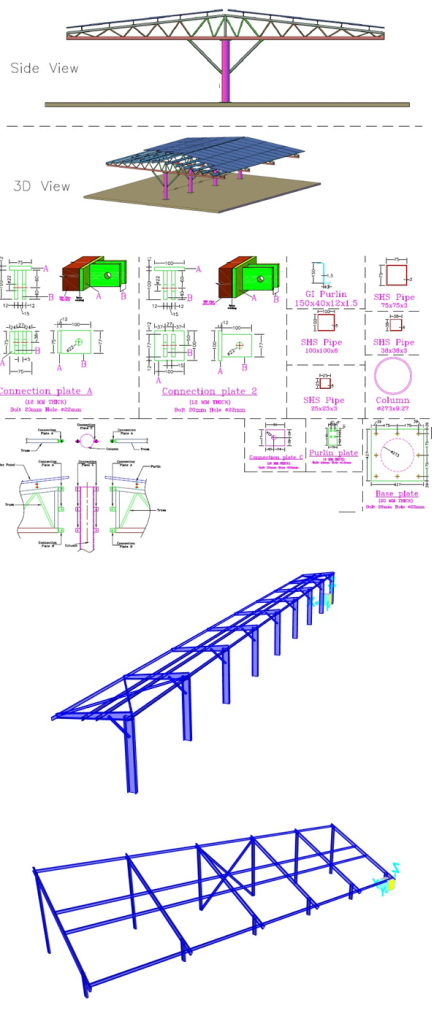

Civil & Structural Design Services

Our detailed structural design department with seasoned resources having dedicated experience of steel with a specialized focus on designing solar racking systems, steel sheds for industrial units, and inverter mounting structures. With a track record of more than 500 MW successful projects completed worldwide, we are dedicated to delivering high-quality, American code-compliant solutions to meet diverse structural needs.

Expertise:

Structural Design: Proficient in designing and optimizing structural frames and connections, adhering to American engineering codes and standards.

Solar Racking: Extensive experience in designing solar racking systems for residential roofs, industrial roofs, and ground-mounted installations.

Steel Sheds: Expertise in the structural design of steel sheds tailored to the unique requirements of industrial facilities.

Inverter Mounting Structures: Specialized in designing robust and efficient inverter mounting solutions for solar installations.

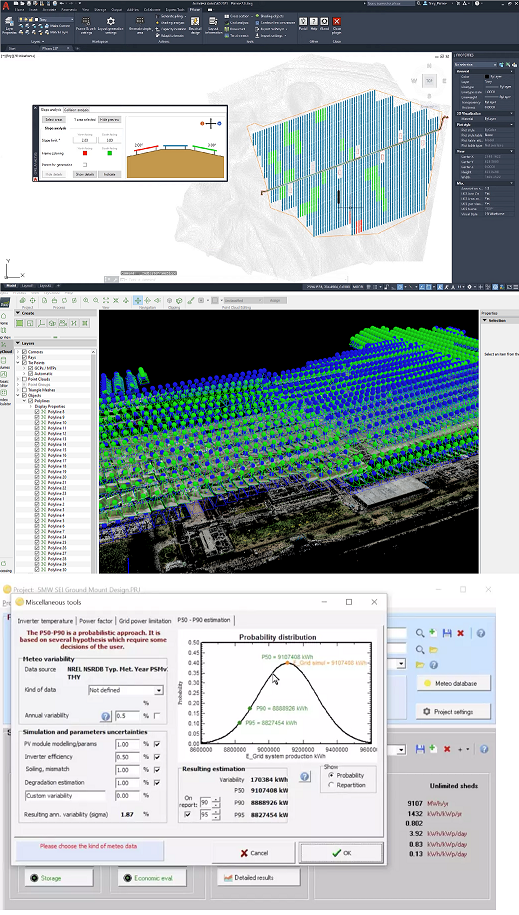

Electrical Design and Yield Calculations

Our Electrical Design Services go beyond meeting industry standards; they are the foundation of your solar project’s success. By entrusting us with your energy yield simulations, CAD layouts, and procurement documents, you gain a partner dedicated to optimizing your solar infrastructure’s performance, reducing costs, and ensuring project efficiency.

Expertise:

Energy Yield Simulations: At Solar Lab, we leverage advanced software tools to provide accurate energy yield simulations. By meticulously analyzing the site-specific solar irradiance data and considering various parameters, we forecast the expected energy generation of your solar plant. Our simulations enable you to make informed decisions, optimize system size, and assess the financial viability of your solar project.

CAD Layout and Detailed Engineering Drawings: Our CAD experts create meticulous and precise layout and engineering drawings that are essential for every stage of your solar project. Our services include:

- PV Module Layouts: We design efficient and aesthetically pleasing PV module layouts, considering factors such as shading analysis, panel orientation, and spacing.

- Stringing: We optimize stringing configurations to ensure maximum energy production while minimizing electrical losses.

- For Construction Detailed Design Package: Solar Lab provides comprehensive, ready-to-implement design packages that cover all aspects of your solar project, from array layout to electrical schematics.

- Cable Design and Loss Calculations: Our experts design the cable infrastructure with efficiency in mind, minimizing energy losses and ensuring the system’s safety and reliability.

Bill of Material: We create detailed Bill of Materials (BOM) a to streamline your procurement process and cost estimation. Our meticulous approach ensures that you procure the right components, avoid delays, and adhere to your budget.

In-Field Testing

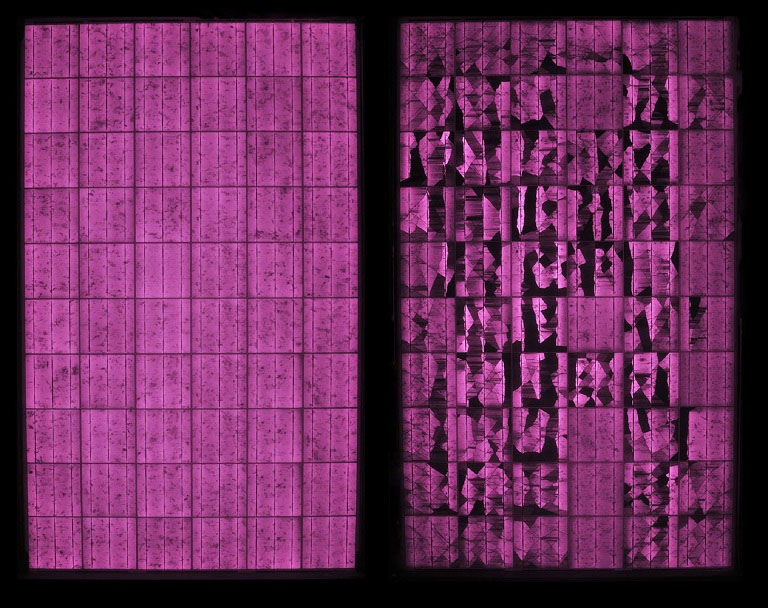

Electroluminescence Imaging

See what’s behind the Glass

PV Modules which appear identical and undamaged might contain damaged solar cells, bad contact fingers or bus-bars. Depending on the damage, this leads to significant reduction in output power.

We use advance Electroluminescence imaging (EL imaging), which require use of INGAAs SWIR Cameras, to verify Solar cell integrity and see through what naked eyes cannot; kind of like taking an X-Ray of the Modules. The image on the left shows two identical PV Modules. One of which has suffered damage during shipment. Can you identify which panel is which?

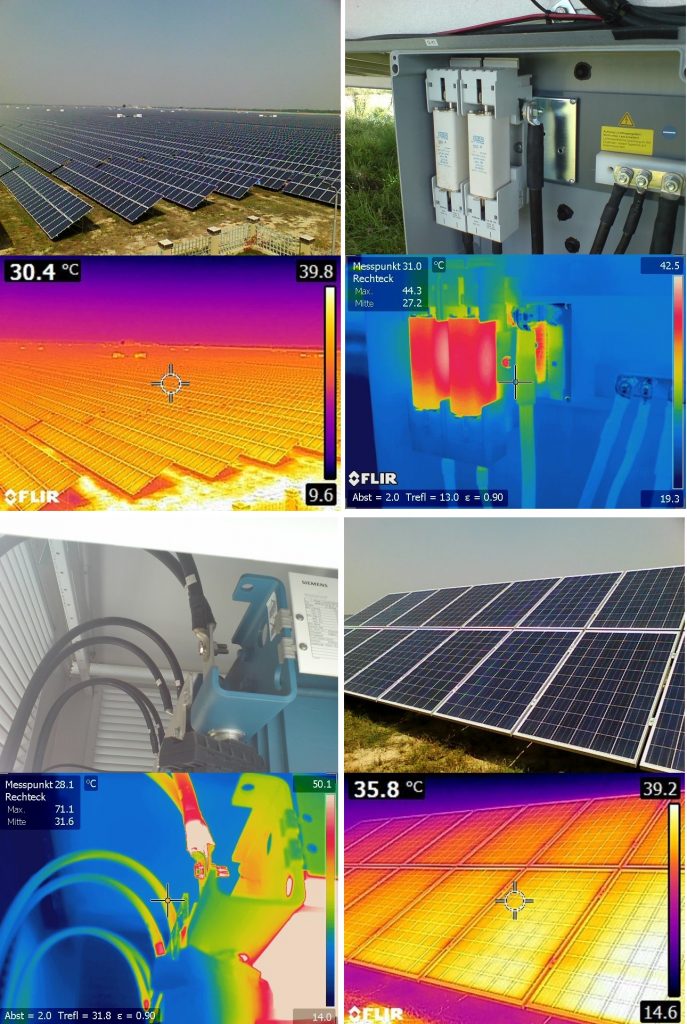

Thermal Imaging

The thermographic inspection of photovoltaic systems allows the fast localization of potential defects at the cell and module level as well as the detection of possible electrical interconnection problems. The inspections are carried out under normal operating conditions and do not require a system shut down. Classification and assessment of the anomalies detected require a sound understanding of solar technology, knowledge of the system inspected, and additional electrical measurements.

Thermal imaging is not just limited to inspection of PV modules, it can be used to carry out inspections for switchgears, electrical terminations fuses, MC4 connectors and diodes. This is particularly useful to spot components that are overheating and are prone to premature failure.

When used properly, thermal imaging is an effective tool to identify faults at an early stage, requiring zero downtime and quickly narrow down the arrays with defects. Our team identifies these and further carries EL imaging and IV tracing and informs the clients on the next steps